Precautions for the use and maintenance of laser engraving machine in winter

Winter is the most prone to failure stage for the laser engraving machine, because the temperature is low and it is easy to freeze, which is a fatal blow to the laser tube. The CO2 laser tube is made of glass, and it is easy to freeze and crack the laser tube at low temperature. How to maintain for new users?

The CO2 laser tube of the laser engraving machine is cooled by water circulation, and the temperature is generally 25°C. In high latitude areas, the weather is cold in winter. In order to prevent the laser tube from being frozen and cracked, users should take anti-freezing measures. For the maintenance of the laser tube of the laser engraving machine, there are the following three suggestions:

(1) Pay attention to the indoor temperature, which should not be lower than 0℃, especially the night temperature, and keep the indoor temperature not lower than the icing critical value.

(2) Empty the liquid in the laser tube after the daily work is completed to prevent freezing. Also pay attention to check the circulating water status before starting up.

(3) Pay attention to keeping the circulating water clean. The circulating water of the laser tube needs to use pure pure water or mineral water. However, due to various reasons, many customers choose tap water as the circulating water. If tap water is used, the water needs to be changed frequently to ensure that the water is clean.

Specific measures to prevent freezing of laser engraving machine in winter

1. After using the laser machine, first disconnect the main power supply, turn off the water pump or chiller, disconnect the silicone tube at the water inlet and outlet of the laser tube, and drain the water inside. The laser tube with power> 60W can also be blown clean with an air pump or a small air compressor.

2. If the laser tube is cooled by a water pump, pay special attention. There is a thick black tube in the water circulation of the water pump, which is water protection. Also make sure that the water inside is clean, otherwise it will freeze and crack the water for protection.

You can also remove the laser tube and pour out the water. In this case, the position of the laser tube may change slightly. Re-dimming is required when reinstalling.

3. There is a sewage outlet and a rotating head under the chiller. The water can be released after screwing it down, which is very convenient. After the water is drained, the chiller can be placed in a place where the temperature is relatively high. Use it next time and add pure water again.

If you find it troublesome, you can add antifreeze. According to local temperature changes, the ratio of antifreeze to water is not the same. You can come to or consult an antifreeze vendor based on the actual situation.

4. The laser marking machine or high-power machine (500W) cannot add antifreeze, because the working principle of the laser inside is different. There will be more steps. Turn off the machine, turn off the cold water, and find a tube with a diameter of 8 mm. Unplug the inlet and outlet pipes and drain the water inside. If there is any residue, the inside may be cracked and damaged.

Customers who use 500W laser engraving machine must ensure that the room temperature is stable.

How to choose a laser engraving machine?

With the rapid development of science and technology of the times, more and more lasers are integrated into our daily lives, and are widely used in various fields such as industry, medical treatment, commerce, military, scientific research and so on. Many people are not unfamiliar with the term laser, and in the field of laser engraving, there are various brands of laser machines on the market, which are dazzling. Guangzhou Dragon Diamond 10-year professional laser equipment manufacturer, teaches everyone how to choose a good laser engraving machine.

The working principle of the laser engraving machine is that the laser produced by the laser is transmitted by the reflecting mirror and irradiated on the processed item through the focusing mirror, so that the surface of the processed item is subjected to strong heat and the temperature increases sharply, and it melts or vaporizes rapidly, in line with the running track of the laser head. So as to achieve the purpose of processing. Connect to the computer via a data cable or USB, install the matching engraving software in the computer, and then use the software to input the text and patterns you need into the laser engraving machine control system. The whole operation process is very simple, and users do not need to learn the knowledge of laser engraving machine professionally.

After understanding the working principle, let's take a look at which aspects should be used to select the machine?

1. Determine the processing material: According to the different laser generation, lasers are divided into CO2 and optical fibers. CO2 is mainly used for non-metal engraving and cutting, and optical fibers are mainly used for metal marking. Generally speaking, the laser engraving machine refers to the CO2 laser engraving machine. , Also called carbon dioxide laser engraving machine, it has three basic functions of engraving, cutting and hollowing.

2. Determine the content of the product: Determine the processing method according to the content of the product, whether it is engraving or cutting. If it is engraving, it depends on the specific requirements of material hardness and engraving depth. If it is cutting, determine the maximum cutting thickness of the material, so as to choose the right one. The laser tube power.

3. Determine the product size: Choose the appropriate model according to the product size. Generally, the laser engraving machine is named after the flat processing format. For example, 1390 is the processing format of 1300*900 mm. But note that the larger the format is not the better. In addition to the high price under the same configuration, the average laser output of some poor-quality machinery and equipment will be unstable at each point of the large format, resulting in slightly worse accuracy. So choosing the right countertop is the most correct.

4. Laser power: According to the different processing materials and content, the appropriate laser tube wattage should be selected. For crafts such as carving bamboo, wood, paper, etc., high-power laser tubes are not needed, but if carving ceramics, glass, purple sand, stones, etc., harder The material needs to increase the power appropriately. If you cut thick acrylic boards and other plates, you must choose a high-power one according to the thickness to achieve a multiplier effect.

5. Engraving speed: The speed of speed directly affects shipments and costs, and is often the key to receiving orders and making money. So how to determine the speed of speed, it is recommended to send materials directly to the manufacturer for proofing, and engrave the same material and pattern size , Under the same effect, the comparison speed is fast and slow. Don't just look at the parameters on the Internet. The engraving speed is different for different materials and effects.

6. Engraving accuracy: The biggest difference between laser engraving and traditional engraving equipment and manual engraving is its high accuracy. It also compares the accuracy of processing the same workpiece. Check whether the engraving shading is smooth, whether the writing is clear, whether the cutting edge is smooth and free of burrs, only by comparison. To see the difference, you can't see the difference just by looking at the parameters.

7. After-sales service: The important thing to buy machinery and equipment is the manufacturer’s after-sales service. No matter how high the quality of any manufacturer is, no matter how good the assembly process is, it is impossible to guarantee that the machine is not broken or malfunctioning. In addition, we may encounter some problems at any time in operation and use. In emergencies, we should choose a regular manufacturer, have a good after-sales service system, and be able to provide technical support at any time, so as to truly solve the various obstacles we encountered in the process of use.

8. Manufacturer qualification: The qualification of a manufacturer is a quick manifestation of its comprehensive strength and years of production experience. When we search and select equipment on the Internet, we can first select several powerful manufacturers by checking the establishment time of the manufacturer and the age of the store, and then Do an in-depth investigation and comparison, otherwise it will be easy to be distracted by some low-priced small manufacturers, and get wrong judgments and can't choose a really good machine.

9. On-site inspection: On-site inspection before purchasing the machine is a very important link, because there are too many manufacturers of all kinds on the market, and the gap between the online quotation and the parameter configuration will be very big, which causes us to be dazzled when we choose. Which one to choose, so take the processing materials to the factory for on-site inspections, on-site proofing to test the machine performance, compare the machine assembly details, and comprehensively investigate the overall style and after-sales service speed of a manufacturer, so that you can choose the most cost-effective machine that is most suitable for you.

(Affected by the global epidemic, on-site visits are not easy to achieve. Guangzhou Dragon Diamond invites you to make a video call, and operate the machine on site to show you our full range of product performance and ensure that you are satisfied! Buy with confidence and use it comfortably!)

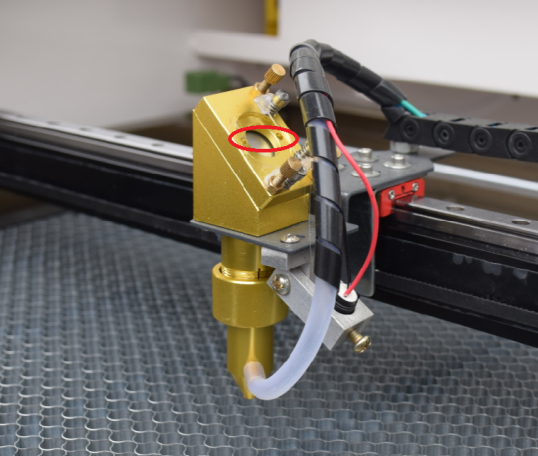

Focusing mirrors should be placed with the raised side facing up.

In this way, the center of the woodworking engraving machine in the X and Y directions is determined, which is equivalent to the origin of the workpiece. Use the engraving machine to accurately align the direction of the material, set a straight bits on the spindle, and then drop the tool on the table, run the machine along one side of the material, and use the gap between one side of the material and the bits find the direction of the material.

Notice on the precautions for the use of CO2 laser tubes in summer

With the influence of factors such as the increase of temperature in summer, the increase of air humidity, and the sharp increase of electricity load in some areas, the failure rate of CO2 laser tubes in summer is obviously higher. In order to ensure the stability of laser tubes in summer, reduce the failure rate of laser tubes Attention should be paid in summer:

1. In summer, the laser tube cannot use antifreeze, electrolyzed water, glass water and other liquids with antifreeze function as the cooling medium. The antifreeze, electrolyzed water, glass water and other liquids must be replaced with pure water.

2. Regularly clean the water chiller and water circulation system of the laser equipment to ensure that the water protection switch of the laser equipment functions normally and the waterway is unblocked. The water flow should meet the water flow requirements of the laser tube.

3. The water temperature of the chiller should be controlled below 35°C, and the temperature difference between the room and the room should not exceed 5℃ (positive in winter and negative in summer) to avoid failures such as deformation of the laser tube cavity, inner tube rupture, and window mirror explosion caused by excessive temperature difference.

4. Carry out the investigation of the high and low voltage wires of the laser tube to ensure reliable connection and protection of the high and low voltage wires of the laser tube. Once the high and low voltage wires are found to be aged or broken down, the high and low voltage wires should be replaced immediately.

5. All laser tubes (≥120W) need to use 50kV high-voltage wires. The length of the high-voltage wires should be as short as possible, and the joints should be as few as possible. It is not allowed to wind or roll the high-voltage wires. If there are excess high-voltage wires, they should be cut off. And the high-pressure joints should be far away from metal and water pipes to avoid ignition of the high-pressure joints.

6. When the high-pressure glass bead or high-voltage wire joint of the laser tube ignites, the high-pressure glass bead or high-pressure joint should be reconnected. If there is oil stains at the connection, the oil stains must be cleaned up before reconnecting.

7. Keep the high-pressure end and high-pressure joints of the laser tube clean. If the high-pressure end and high-pressure joints are contaminated by oil and dust, it is easy to cause high-pressure ignition. Air pump and alcohol can be used to clean up pollutants regularly, and insulating materials can also be used for isolation treatment.

8. When the external voltage is unstable or lower than 210V, a voltage stabilizer can be installed or replaced with a stabilized laser power supply of the same model to avoid abnormal or inconsistent power of the laser tube due to unstable external power or low voltage. Stability and other phenomena.

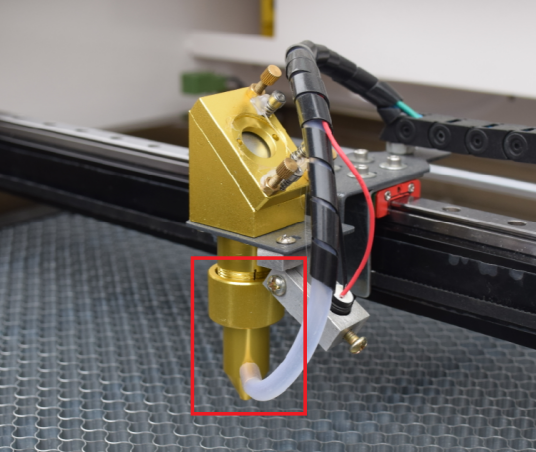

9. No matter whether the laser tube enters from high pressure or low pressure, it will not affect the use of the laser tube, but it must be ensured that the water outlet of the laser tube body is vertically upward, and the installation is based on the principle of low inlet and high outlet. There is no obvious air bubble in the water-cooled tube .

10. The water inlet and outlet pipes of the laser tube should be far away from the laser tube body, especially the tube body of the laser tube light outlet (generally the temperature of the laser tube light outlet tube body is 40-60 ℃), to avoid condensation or excessive temperature of the water pipe low causes the outer tube of the laser tube to break.

11. Keep the laser tube window mirror clean and pollution-free. Clean up the contaminants of the laser tube window mirror with a bamboo cotton swab moistened with absolute ethanol (alcohol) regularly to prevent the laser tube window mirror pollution from affecting the laser tube spot and power.

The control system of cnc engraving machine is generally controlled by computer or directly by the handle card.

1. Adopt computer control

the computer completes all the calculation work.

When the engraving machine is working, the computer is in a working state and cannot perform other typesetting work.

The computer is in an exclusive state. This is the basic working form.

The advantage is that you can use various programs on the computer to directly modify the pattern, so that your own processing pattern can be sent to the engraving machine more quickly.

The bad thing is that you need a computer. The principle is: use a plate to connect to the computer, and then connect the line to the engraving machine control system.

2. Using the control of the handle board

the controller performs typesetting while the engraving machine is working, and the direct version is connected for operation.

The advantage is that it can be operated directly, which is convenient for customers who are not using a computer for the time being.

The disadvantage is that the buttons of this controller will be easily broken. In addition, the design pattern needs to be designed and sent to the controller in other places.